NUFORM Machining Modeling

The NUFORM System provides extensive solid modeling capabilities. The machining simulation can be as simple or complex as necessary. All types of machine can be simulated. In general, the machine simulation is kept to only those components of interest. Various components can be hidden or displayed. Collisions are shown and a log for review and playback is kept. An STL model of the machined part can be saved.

Machine and Process simulation Examples

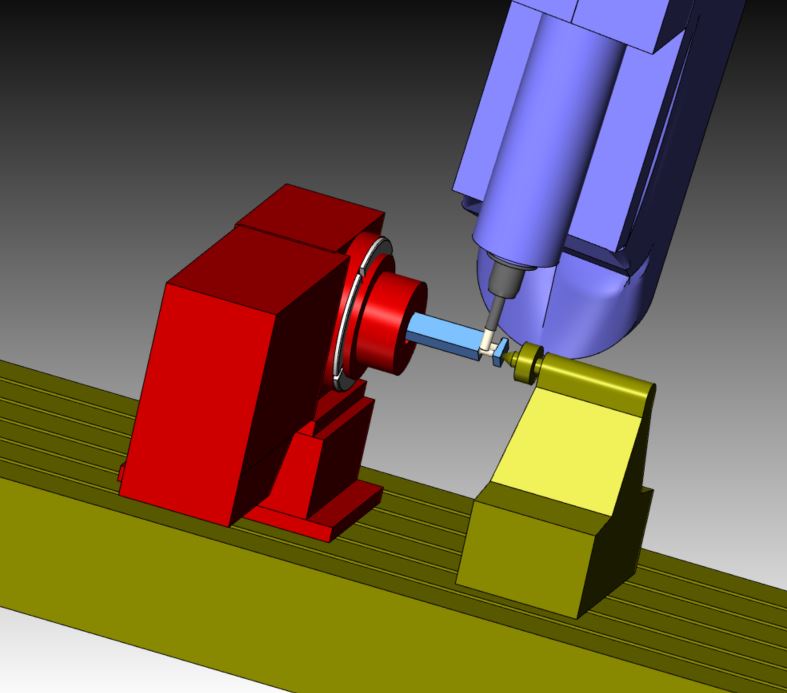

Boston Digital BD605

The machine has a tilting spindle, tilting about a point roughly 6 inches below the face of the spindle. Such provides for high performance machining by reducing X and Z motion.

The machine has a tilting spindle, tilting about a point roughly 6 inches below the face of the spindle. Such provides for high performance machining by reducing X and Z motion.

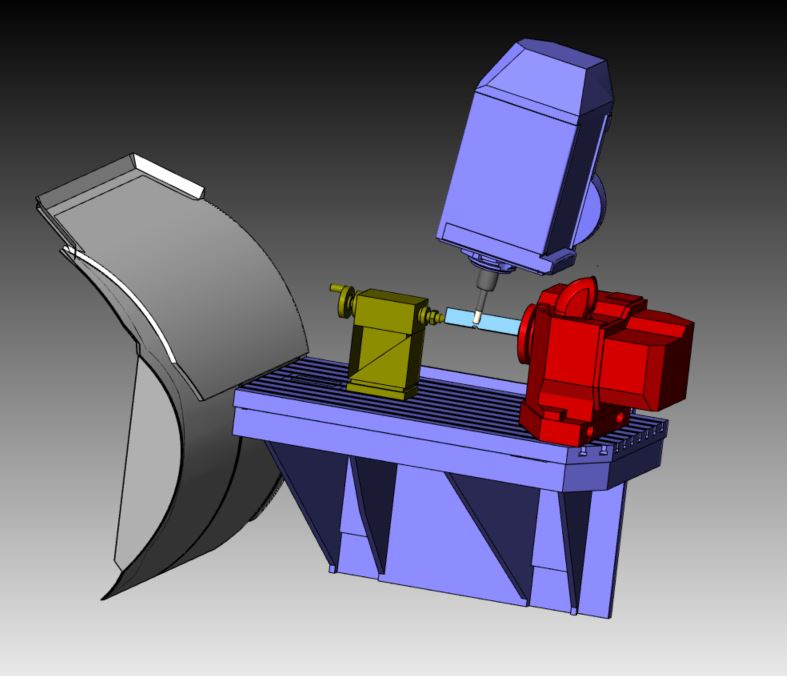

DMG DMU60

The DMG DMU60 has a tilting spindle where the center of rotation is 12″ above the face of the spindle. The machine has numerous possible collisions areas both against the headstock on the right hand side of the table as well as the tailstock and tool changer on the left.

The DMG DMU60 has a tilting spindle where the center of rotation is 12″ above the face of the spindle. The machine has numerous possible collisions areas both against the headstock on the right hand side of the table as well as the tailstock and tool changer on the left.

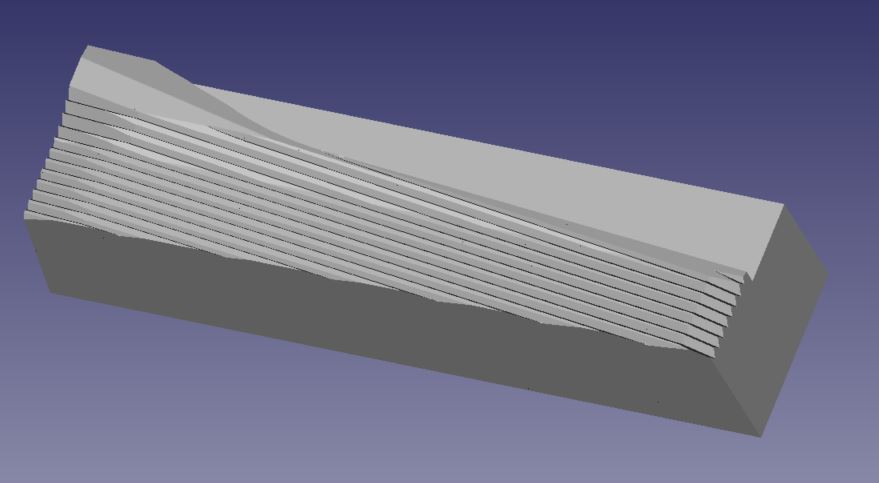

Machined Thread Rolling Die

Thread rolling die machined with solid raw stock model.

Modelling machining allows for checking that there is no interference with the part and machine components.